The raw material processing of stainless steel before pipe making is also very critical, and every process is a factor that determines the quality of pipe fittings. Today, the editor of Gangzheng will take you to understand the flattening and slitting process of stainless steel coils.

1. Kaiping stainless steel coil

Most of the stainless steel coils are made in whole rolls when they leave the factory, mainly for the convenience of transportation; generally when they are in the hands of the supplier, they will be flattened by professional stainless steel flattening equipment for the convenience of use. This process is called Kaiping; and the Kaiping process is most prone to problems such as scratches and insufficient length.

In order to prevent the steel coils from deforming after opening, it is best to lay them flat. If there are a large number of them, they can be pressed together and separated by pads. Also, pay attention to moisture prevention, as they will deform once they become damp. Of course, it can also be placed upright, but it should not be placed for too long, and deformation will occur after a long time, unless it is a floor with a thickness of 2.0mm or more.

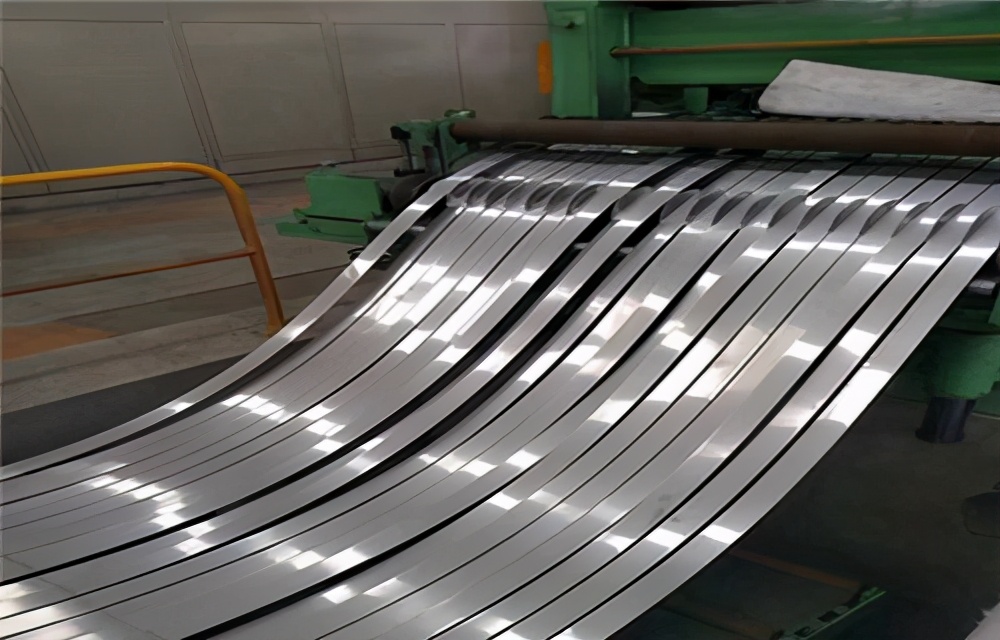

2. Slitting of stainless steel coils

The slitting of stainless steel coils is to divide a certain width of stainless steel strip into one or several stainless steel coils according to the specifications required by the production. The slitting process is prone to problems such as scratches, uneven rolls, high edge burrs, insufficient width, collapsed rolls, edge waves and knife bends.

The problems that occur in the flattening and slitting of stainless steel coils, if they are serious, will directly affect the subsequent pipe-making process, resulting in large errors in the size of the stainless steel pipe produced, rough surface, and insufficient straightness of the pipe fittings; so you must think To purchase high-quality stainless steel pipes, the raw material processing of the manufacturer is also very important. The stainless steel raw materials of the Gangzheng manufacturer all use the cold-rolled large plates produced by Baosteel, Taiyuan Iron and Steel, Zhangpu and other large factories. It has large workshops and advanced The production equipment ensures that each product maintains its high quality when it leaves the factory.

Post time: Jun-17-2017